Introduction to Electrodeposition (ED) Experimental Laboratory

Outline

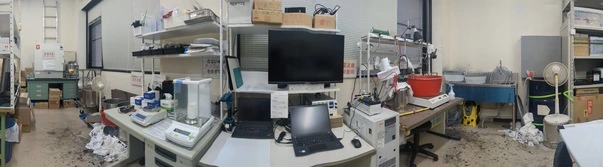

- We have a laboratory in Ookayama Campus of Institute of Science Tokyo (Meguro-ku, Tokyo) where we can conduct electrodeposition (ED) experiments.

- A variety of experiments can be conducted: evaluating ED behavior such as throwing power, identifying ED mathematical model parameters that can be used with the ED simulator "EDESFEM", etc..

- As the ED lab is a university facility, people from outside the university can also conduct experiments as they like by re-configuring and adding devices.

- ED paint should be prepared-and-sent by a paint manufacturer or collected-and-sent from an actual ED line. (The lab does not have equipment for making ED paint.)

- Pre-treated plates (test pieces) should be manufactured and sent by test piece companies. (The lab does not have equipment for making test pieces.)

- If you would like to visit the ED lab., please feel free to contact us by email.

Electric Devices

- DC Power Source: TAKASAGO, ZX-S-800HA

- External Resistor: TamaOhm, THR series, For replication of solution/membrane resistance

- Shunt Resistor: Ohmite, 15FR250E, For current measurement

Water-related and Drying Devices

- Constant Temperature Water Circulator: EYELA, CTP-3000, For controlling paint temperature

- Magnetic Stirrer: Nissin Rika, SW-050L, For paint stirring

- Water Spray Gun: Asone, WGN-2, For rinsing test pieces after painting

- Electric Oven: Yamato Scientific, DKM600, For baking painted test pieces

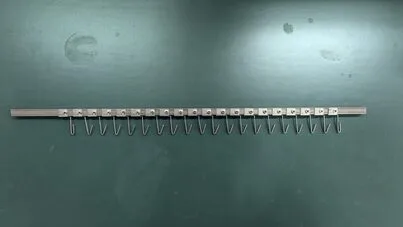

- Test Piece Hanger: Yamako Electric Manufacture, Custom-made, For hanging test pieces

- Others: SUS316 tank/pot, Fan, Air blower, IR heater, Throw-in heater, etc.

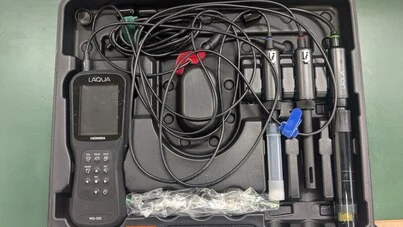

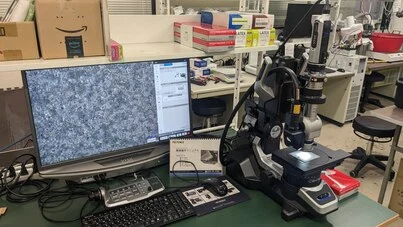

Measurement Devices

- Data Logger: KEYENCE, NR-X100 series, For logging the time histories of voltage, current, and temperature

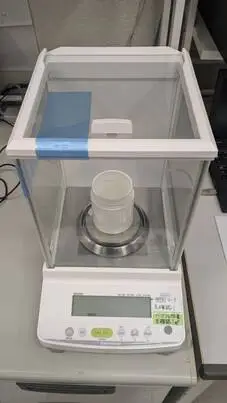

- Electronic Balance: SHIMADZU, ATX224, For measuring the mass difference of test pieces before and after painting

- Film Thickness Meter: Fischer, DMP20, Both the magnetic induction type (for Fe plates) and eddy current type (for non-Fe/Al plates), For measuring the coating thickness

- Water Quality Meter: HORIBA, LAQUA WQ-330PCD-S etc., For measuring the electrical conductivity and pH of paint

- Radiation Thermometer: HORIBA, IT-545S, For spot measurement of temperature

- Optical Digital Microscope: KEYENCE, VHX-970F, 20-2000x, For observing the surface of test pieces before/after painting/baking

One-Plate Test

- Anodic Pot: Clover, StockPot 10011922

- Test Piece Hanger: Self-made

- Test Piece Size: 70 x 75 x approx. 0.8 mm or 70 x 150 x approx. 0.8 mm

4-Plate Box (4BOX) Test

- Case: Masatani, Custom-made, Rigid PVC

- Separator: Kimoto Rubber Industry, Custom-made, Silicone rubber

- Jig and Balloon: Self-made

- Test Piece Size: 70 x 150 x approx. 0.8 mm

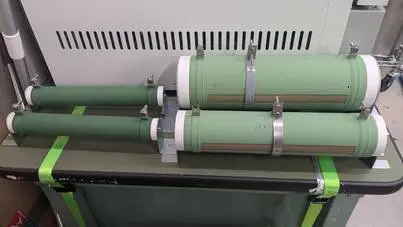

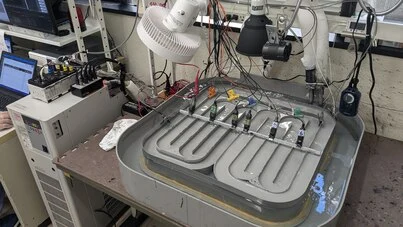

Circulating Bath (Circuit) Test

- Circulating Bath: Masatani and Sakai Work, Custom-made, Rigid PVC and SUS316

- Circulating Pump: SEAFLO, SP-DS-WP-280GPH

- Test Piece Hanger: Yamako Electric Manufacture, Custom-made, Rigid PVC and SUS316

- Test Piece Size: 70 x 75 x approx. 0.8 mm

Actual Line Carbody Surface Potential Measuring Device Ver. 1

- Data Logger: GRAPHTEC, GLT400, 20ch

- Waterproof Case: Masatani, Custom-made, Rigid PVC

- Waterproof Plug: Nanaboshi Electric Mfg, NRW-2824

- Electrode: Self-made, For measuring the surface potential of the inner part of the bag-like structure (e.g., inside of the side sill), For both steel and aluminum

Actual Line Carbody Surface Temperature Measuring Device

- Temperature Logger: T&D, Ondotori TR71A

- Sensor: T&D, TR-1106 and TR-5C10

- Waterproof Case: UMIHIME, Waterproof pouch

- Cable Gland: Takachi Electronics Enclosure, RPG7-7B

Back to Homepage